In the district of Neundorf in the municipality of Rosenthal am Rennsteig, two new elevated tanks will supply water for the future. A large pit had to be excavated in bedrock before trenching for foundations and pipelaying could start. Mounted on a 26-tonne excavator, a KRC 140 Bullhead milling attachment from KEMROC completed all excavation work and trenching within expected tolerances and within expected timeframe.

Schwall + Mayer is a respected contractor for building, construction and civil engineering

projects in the greater Thuringia area. At one of its most recent major projects, the building

and civil engineering company completed site preparation work in late summer 2023 for a

construction project of its client ZWT Wasser- und Abwassertechnik GmbH from Bayreuth.

The client was building two new elevated tanks for the local water supply in Neundorf, a

district of the municipality of Rosenthal am Rennsteig (Thuringia). In the run-up to this

work, the site had to be prepared. It was known from site investigation surveys that excavation work would be difficult because the majority, 2,300 m3 out of the total of 3,400 m³,

had to be excavated in solid sedimentary rock known locally as leather slate. To excavate

this hard and tough material, site manager Frank Brendel decided to use their KEMROC

KRC 140 Bullhead milling attachment with full hydraulic quick coupler mounted on the

company’s 26-tonne excavator. After the topsoil had been removed, this combination of

equipment excavated rock down to a depth of 5.50 m below ground level while alternating

between the grinder and bucket to remove broken material. Subsequently, excavating work

had to go even deeper to install foundations, sumps and to excavate trenches for the water

pipes – and thanks to the design characteristics of the Bullhead milling attachment, this was

done with the accuracy and speed required.

Milling with beefy precision

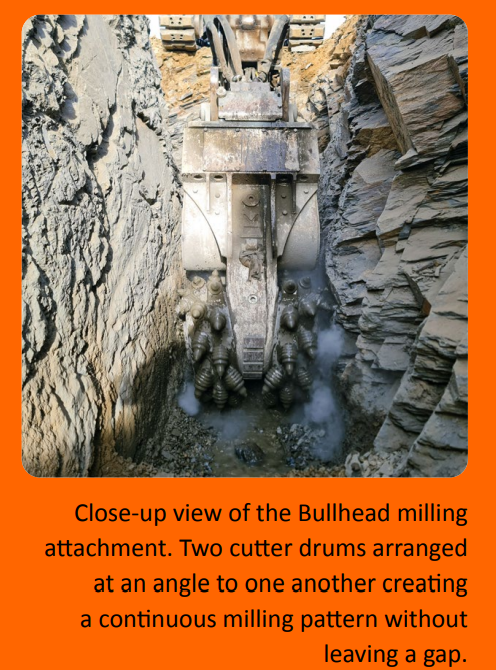

The performance of the KRC range of Bullhead milling attachments from KEMROC raises the bar once again when it comes to trenching. The machines are available in five sizes for carriers from 12 to 50 t operating weight. They have a unique gearbox design with two cutter drums arranged at an angle to one another, with an overall shape that is reminiscent of a bull’s head. When working, the round attack picks on the two cutter drums are so close to each other that an almost continuous milling pattern is created. While conventional transverse cutter attachments leave a mound of rock between the two cutter drums, this material is completely removed in most cases with the KRC Bullhead milling attachment.

The trench is excavated exactly to the desired width without any time-consuming extra

work. In almost all rock types, swinging the excavator arm from side to side to remove

the central hump is no longer necessary. “An additional benefit,” adds site manager Frank

Brendel, “is the size of the milled material that is produced. When milling out the rock,

the machine produces a homogeneous, fine-grained material. For this project, we put the

spoil into temporary storage nearby and will use it later for backfill without any additional

processing.”

Milling technology in civil engineering and pipeline construction

The construction project in Neundorf, including excavating trenches and foundations, took a total of around eight weeks in the summer of 2023 and was already the second major deployment of the KEMROC milling attachment at Schwall + Mayer – and also the second assignment on behalf of ZWT from Bayreuth. Since purchasing the attachment in autumn 2022 (the Thuringian company bought the first model delivered by KEMROC at the time), it has already been involved in numerous civil engineering and sewer construction works in urban areas. More than half of the company’s work is carried out in this segment of the construction industry. As a result, almost all of the company’s excavators are equipped with full hydraulic quick couplers so they can quickly alternate between buckets and other attachments as the situation requires.

Working in an open area, as at the project in Neundorf, was out of the ordinary for the engineers at Schwall + Mayer. Conditions at most of the municipal civil engineering, sewer and pipeline construction sites are usually much more cramped. In the urban environment, another benefit of milling attachments comes into play, adds site manager Frank Brendel: “When excavating trenches in the immediate vicinity of buildings, the advantage of using milling attachments is that they work with little vibration. In this way, we significantly reduce the degree of annoyance to residents, and we avoid damage to the structure of

neighbouring buildings.”