ACD Machine Control: Introducing Anemometers customized for the customers

ACD Machine Control is a 50-year-old family-owned company providing application-based instruments like air velocity monitoring and vibration monitoring. We had a conversation with Prajakt Paralkar, CEO, of ACD Machine Control Company Pvt. Ltd., during Excon 2023 on their latest development and plans.

Could you talk about the products that are being displayed By ACD machines at EXCON 2023?

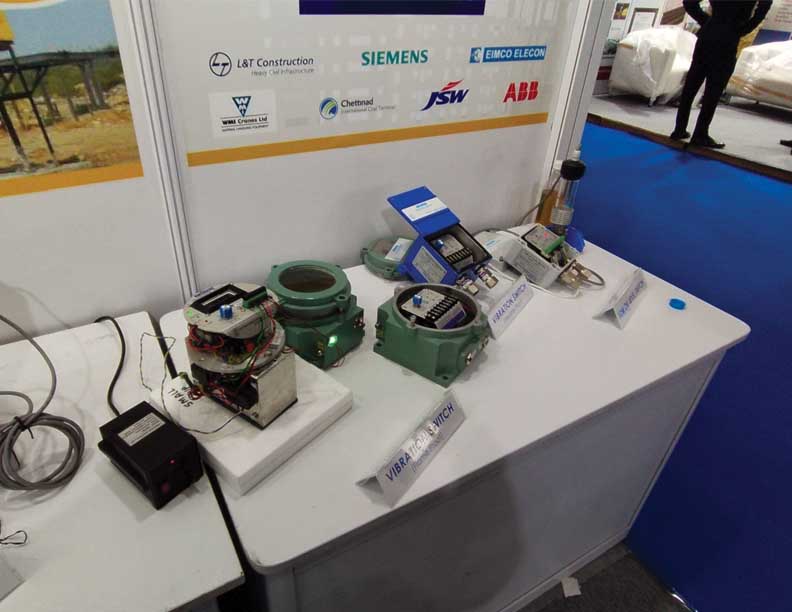

For EXCON 2023, we have the anemometers, and the cup anemometers, which are used for wind monitoring. As per government norms, if the wind goes beyond a certain limit, your crane has to be stopped. Since the government is emphasizing more on safety, this has become a compulsory attachment. Till now, we had a wired instrument. But depending upon the industry feedback, we have developed a wireless instrument, which will be launched in the next couple of months. And the anemometers are what we are displaying here.

What sets ACD Machine vibration measurement and electronic instruments apart from the competitors?

The main difference will be these products are designed and manufactured by us in-house. Several competitors are available in the market mainly traders.

So, there is always a delay in after-sales service from their end. However, since these instruments have been designed and manufactured by us, we can service them anytime. There are cases and our customers in which instruments, which were supplied 10-15 years ago, are still working in the market. And since our products are application-based, we supply several industries like the construction industry, mining industry, pharma, cooling towers, and many more.

Are there any AI technologies or other techniques integrated into the products?

AI is currently being integrated into our products. All our products are all digital. At the moment, we don’t require AI integration into these products. But based upon the customer feedback, and if the customer requires it, we are taking that feedback and trying to integrate those techniques and logic.

Could you talk more about your vibration measuring and electronic instruments?

Vibration is one of the major causes of failure across the machine industry. We have vibration switches, which are an essential safety and machine life-increasing instrument. It is used in VSI crushers and centrifuges. It is installed in the machine and it monitors the vibration. When the vibration goes beyond a set limit, it gives an alarm or danger alert.

Depending upon the user requirement the switches can be integratedinto the system. Before there is any failure or there is any damage to human life as well as the equipment, we can take the necessary actions and prevent any mishaps.

Could you provide insights into the company’s manufacturing facility and the role it’s ensuring in product quality?

Our entire manufacturing is done in-house.We have a manufacturing facility in Andheri, Mumbai. We have two plants; one does the mechanical machining and the otherdoes the electronics. We have an entire SOP by which after every stage, the person checks whether the manufacturing is as per the requirement, whether it is as per the required standards, which will be in the field, or not. We all know, construction is a very intensive industry. Weensure that our products stand up to the requirements of the industry.

Every instrument is individually tested as per the requirements. So, for example, if a certain vibration is expected, the entire equipment is checked to that entire range before being passed on to the customer.

How do you see your company’s growth and development in the coming years?

We are getting a lot of feedback from the customer regarding the integration of AI into the instruments. Hopefully, within the next year, we will be launching equipment that you can build with your logic into the equipment and we hope to grow in that direction as well. All these logic-based rules will be built into the system. Giving customers more flexibility and benefits.So, instead of having different products for each of their requirements, customers can have a single product that has the flexibility of modifying the product functioning as per their requirements.