Layer by layer, the new STRABAG BMTI (STRABAG Baumaschinentechnik International) warehouse in the Weilimdorf district of Stuttgart is growing. ZÜBLIN, together with Putzmeister and their mobile concrete printer KARLOS, has developed an innovative construction process that is unique in the world. As part of their long-standing collaboration, both companies are combining their innovative strength to take 3D concrete printing to a new level. The aim of their research is to be able to offer customers an even more flexible and sustainable printing process in the future.

New technology takes 3D concrete printing to the next level

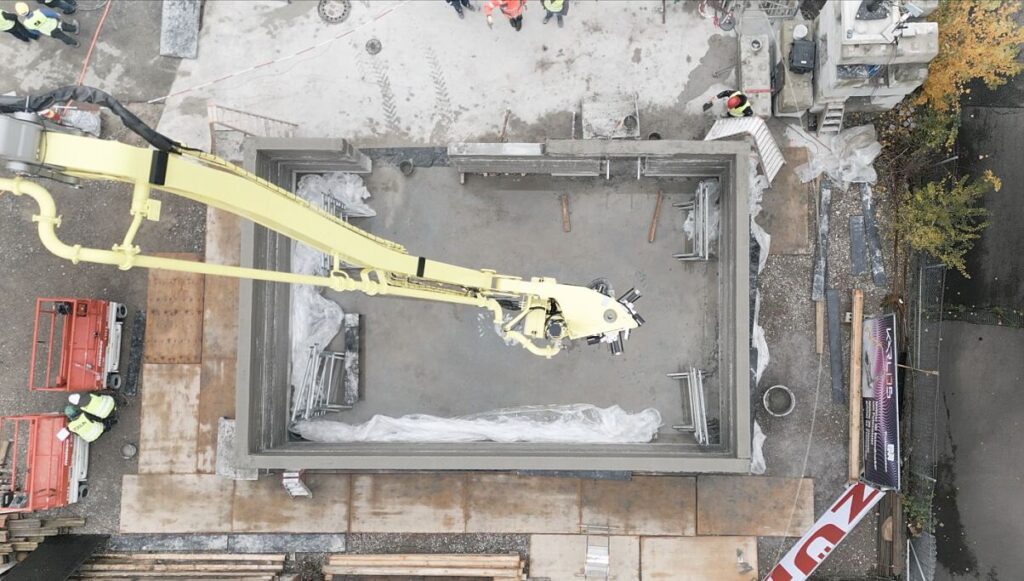

The basis of the new technology is a truck-mounted concrete pump. An automatically controlled mast boom with a reach of 26 meters precisely applies concrete in several layers using a special print head based on a predefined and digital construction plan. This means that storey-high, load-bearing concrete walls are manufactured that enclose the room and thus prevent the spread of flames and smoke in the event of a fire.

The challenges of 3D concrete printing have so far primarily been the lack of scalability of the technology for large-scale projects. So far, printing has primarily been done with so-called portal printers, which are limited to the production of smaller buildings. Compared to other concrete printing processes, KARLOS has greater flexibility and range as a mobile construction machine and therefore offers the potential for scalability even for large projects.

CO 2 -reduced concretes in use

In addition to the complete elimination of formwork work, the economic and ecological advantages of the method include the production of solid wall cross-sections in one operation and the use of CO 2 -reduced concrete. By exclusively using green electricity for the fully electric machine and using CO 2 -reduced concrete, ZÜBLIN and Putzmeister are making an important contribution to making building construction more sustainable in the future.

“On our way to planning and building in a resource-saving and climate-neutral way, we are proud to have developed a highly innovative 3D printing process together with Putzmeister. As a construction company, we are particularly bringing our know-how in the digital planning of building structures and concrete technology to this pioneering innovation,” explains ZÜBLIN board member Stephan Keinath.

Putzmeister CEO Christoph Kaml sees KARLOS as a central element of the company’s strategy: “A high degree of electrification and automation is required throughout the entire work process. Reducing manual work is a crucial factor in dealing with the increasing shortage of skilled workers. As a digital technology of the future, KARLOS is a central building block on the way to the construction of tomorrow.”

3D printing as a productivity driver

Additive manufacturing methods, especially 3D printing, have become an integral part of industries such as mechanical engineering, automotive and aviation. Now they are increasingly conquering construction sites. The connection of the manufacturing steps from the digital planning of the BIM model (Building Information Modeling) to the realization using a 3D printer is revolutionizing the construction processes. Work processes are significantly streamlined and accelerated through automation. As groundbreaking as 3D printing technology is, the human factor remains crucial to the successful implementation of construction projects. ZÜBLIN and Putzmeister are addressing the massive shortage of skilled workers

therefore also with the use of modern technologies. This not only increases productivity, but above all also increases enthusiasm for an exciting and promising construction profession with a future.