Abstatt – In the face of growing environmental awareness and ever more stringent legal regulations, construction machines are increasingly being equipped with electric drives. This concept allows work to be completed with zero local emissions and thereby reduces the exhaust and noise levels that have become commonplace, for example, on construction sites in densely populated residential areas as well as in city centers. Another use case for this technology is in machinery and devices for underground mining. Such applications frequently require complex technical solutions in order to remove the exhaust gases and heat produced by internal-combustion engines. At bauma, Bosch Engineering is presenting a newly developed high-performance solution for battery voltages of up to 800 volts, which further increases the range of applications for construction machinery. “The latest generation of our powerful electric drive system combines high power density, compact dimensions, and optimum efficiency. As a result, even construction machinery with high power requirements and limited installation space, such as wheel loaders, can now be equipped with electric drives,” explains Philipp Kurek, who is responsible for off-highway and maritime solutions at Bosch Engineering. The improved overall efficiency results in a reduced total cost of ownership (TCO) of the construction machine across its service life. Depending on the application profile, electrification thus also provides potential financial benefits over diesel-hydraulic powertrains. In addition, the electrification solution from Bosch Engineering offers great flexibility in combination with tailored transmission solutions from Bosch Rexroth, such as the new eGFV9100 coaxial gearbox.

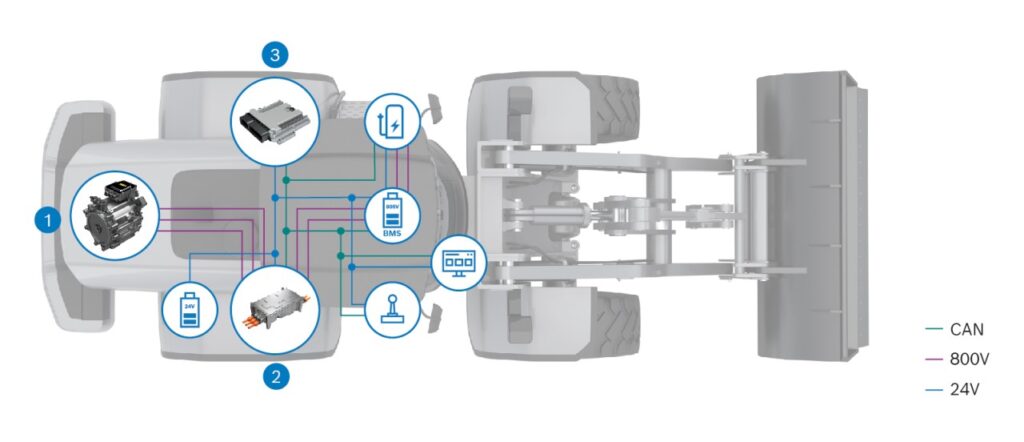

The 800-volt drive system consists of the Bosch electric motor SMG230 and a highly efficient inverter equipped with silicon carbide power modules. The motor is designed for system voltages of 400 to 850 volts. In an ideal voltage and temperature range, it offers a continuous power output of up to 200 kilowatts and around 250 newton meters of torque. Up to 550 newton meters of peak torque can be delivered on a short-term basis. Thanks to the 800-volt technology, the power density has also been increased significantly. The new motor delivers up to 80 kilowatts more power than a comparable 400-volt machine with identical weight or, with the same level of performance, boasts more compact dimensions and a much lower weight. The 800-volt inverter with silicon carbide semiconductors, which was tailored to the exact requirements of the SMG230, boasts an impressive efficiency of more than 99 percent. The silicon carbide semiconductors in the power modules enable faster switching operations and steeper switching slopes, meaning that significantly less energy is lost in the form of heat.

The electrification components from Bosch Engineering for construction machinery applications are designed to be extremely robust, reliable, and durable. The safety and diagnostic concept is based on established standards from the automotive domain and has been adapted to the specific requirements of mobile machinery. The compact dimensions enable straightforward integration even into tight installation spaces, meaning that existing device platforms can also be converted to eco-friendly electric drives. What is more, Bosch Engineering supports its customers in integrating the drive system into their machinery as well as with the actual application of the system.

The new Rexroth eGFV9100 coaxial gearbox fitted to the SMG230 will be unveiled at bauma at booth A3/327.

In addition, in cooperation with Bosch Rexroth, Bosch Engineering supports its customers in integrating the drive into the construction machine, including application development, based on the open ECOsystem BODAS.