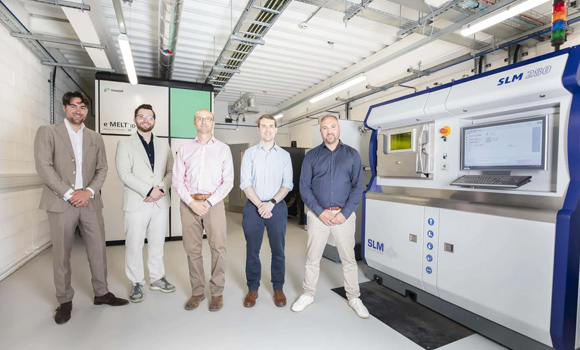

The United Kingdom Atomic Energy Authority (UKAEA) has added two advanced Additive Manufacturing (AM) machines to its new Central Support Facility (CSF). These machines — one from Freemelt AB and another from Nikon SLM Solutions — will help the UKAEA develop and produce critical components for fusion energy systems.

UKAEA has brought in an eMELT Electron Beam Powder Bed Fusion (PBF-EB) machine from Freemelt, a company based in Mölndal, Sweden. This machine will be mainly used to build tungsten components, layering them onto other metals like copper-chrome-zirconium, stainless steel, and a special fusion-grade steel called Eurofer 97.

The second machine is a SLM280 Laser Beam Powder Bed Fusion (PBF-LB) system from Nikon SLM Solutions in Germany. Supplied by Kingsbury Machine Tools and supported by Additure, this machine is designed to explore complex component shapes and multi-material builds that are expected to be crucial for the next generation of fusion reactors.

Both systems will play a key role in developing plasma-facing components, which need to withstand the extreme heat and radiation inside fusion machines. These AM methods will also help reduce dependence on traditional processes like welding, which are time-consuming and limit design flexibility.

Fusion energy is often described as a potential game-changer in the quest for clean, low-carbon power. But it comes with unique engineering challenges. Inside a fusion reactor, hydrogen isotopes — deuterium and tritium — are heated to over 100 million degrees Celsius, forming a super-hot plasma where nuclei fuse and release energy. Components used in such environments must survive high temperatures, neutron bombardment, and intense magnetic fields, often all at once.

Because fusion devices are still in development, most components are made in small batches with unique designs. This makes Additive Manufacturing a natural fit. AM technologies allow for greater design freedom, lower production volumes, and cost control, which is especially useful during the early stages of building fusion machines.

Roy Marshall, Head of Operations for Fabrication, Installation and Maintenance at UKAEA, explained,

“Future fusion power plants will need thousands — possibly millions — of parts with intricate designs that can withstand extreme conditions. We believe Additive Manufacturing is key to making fusion commercially viable. With these two AM machines, we’ll be able to demonstrate how to produce these parts at scale — something that would be extremely expensive or even impossible with conventional methods.”

Marshall also pointed out that having both electron beam and laser beam AM systems under one roof is a first in the fusion field.

“Many organisations have one or the other, but rarely both. We’ll now be able to compare, validate, and scale both approaches at the same facility.”

The new Central Support Facility combines advanced manufacturing equipment, workshops, and specialist teams in one space. It’s designed to encourage close collaboration between engineers and researchers working on fusion technology. With these tools in place, UKAEA is aiming to build a production-ready pipeline to support future large-scale fusion projects.

Industry leaders welcomed the collaboration:

Viktor Valk, Regional Manager, EMEA at Freemelt said,

“We’re proud to support UKAEA’s work toward making fusion energy a reality. Using our eMELT system to print tungsten components that can handle extreme fusion environments is a key milestone for us.”

Christoph Barefoot, Regional Business Director for the UK and Nordics at Nikon SLM Solutions, added,

“Fusion is the future of energy, but it requires bold thinking and strong partnerships. Our Selective Laser Melting technology will help UKAEA produce complex, high-performance parts at scale — moving fusion a step closer to becoming a commercial energy source.”

The next steps for UKAEA include experimental builds using both machines and testing the strength and performance of printed parts. Early projects will focus on layering tungsten with copper-chrome-zirconium — a critical combination for fusion energy systems.