With India’s infrastructure sector on an unprecedented growth trajectory, component manufacturers are redefining what “Made in India” stands for. Mother India Forming (MIF), a leader in precision cold roll forming and structural assemblies, is setting benchmarks for safety, sustainability, and global manufacturing excellence. Ahead of EXCON 2025, the company discusses its vision, technological advancements, and contribution to India’s emergence as a world-class manufacturing hub.

What do you intend to showcase at EXCON 2025?

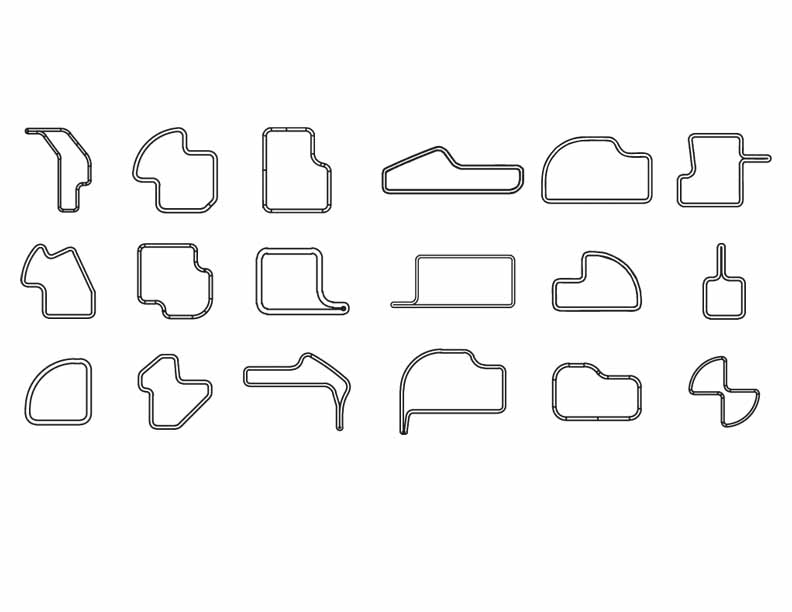

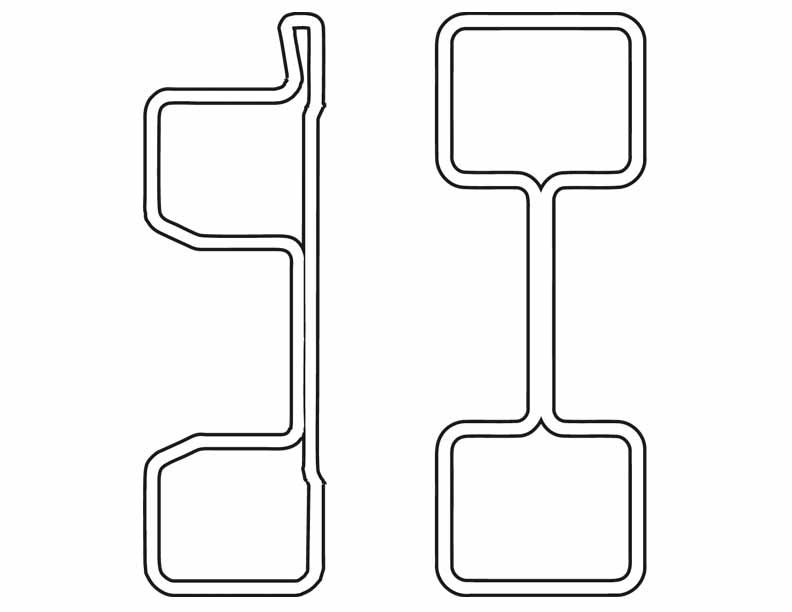

At EXCON 2025, we’re showcasing the evolution of Indian manufacturing — from component supplier to global engineering partner. Our exhibit will feature ROPS/FOPS-compliant cabin structures, modular assemblies, and precision roll-formed profiles for construction and formwork systems.

The highlight is our “Design-to-Fit” ecosystem — an integrated approach that brings together roll forming, all-electric CNC bending, robotic welding and ready-to-fit assemblies under one roof. It demonstrates how MIF enables OEMs to accelerate product development, improve build consistency, and achieve sustainable manufacturing outcomes.

What are the major manufacturing challenges that OEMs face with tubular or roll-formed components, and how is MIF addressing them?

Consistency, tooling precision, and lead time have always been key challenges in this domain — and we’ve built our processes to address them holistically.

At MIF, servo-controlled roll forming lines, robotic welding systems, and digital quality tracking ensure repeatable accuracy across high-volume runs.

We’ve also established in-house tooling design and manufacturing capabilities to reduce development cycles, maintain cost control, and enhance product reliability. This combination of precision and process integration enables our customers to achieve global standards within competitive timelines.

How is MIF helping OEMs localise and customise roll-formed or tubular components for the Indian market?

That’s one of our strongest areas of collaboration. Many global OEMs approach us with components that were previously imported but need customisation, localisation, or cost optimization without sacrificing performance.

We specialise in developing India-ready solutions that adhere to international safety and quality benchmarks. Our approach ensures manufacturability, reduces logistics dependency, and strengthens the domestic value chain — all while maintaining the precision global OEMs expect.

How does MIF ensure flexibility and agility when it comes to design changes or engineering modifications?

Flexibility in design modification is the core of MIF’s operating philosophy.

We work closely with OEM design and R&D teams to optimise profiles for performance, cost, and manufacturability. Because we manage every stage — from CAD/CAM modelling and tool design to forming and finishing — we can implement design changes swiftly and accurately. This agility enables our clients to reduce the time from design freeze to production and respond more quickly to evolving market needs.

How is MIF contributing to India’s ‘Make in India for the World’ initiative through localisation and export readiness?

We are deeply aligned with the ‘Make in India for the World’ mission. Our infrastructure and systems are designed to support global OEMs in localising critical components without compromising safety or quality benchmarks.

MIF has successfully transitioned several imported cabin and tubular assemblies to local production — achieving global certifications while enhancing cost efficiency and supply chain resilience. For us, localisation is not just about substitution; it’s about building India’s capability to supply globally competitive, world-class components.

How does MIF’s integrated manufacturing ecosystem deliver value to OEMs seeking end-to-end solutions?

That’s exactly what MIF offers. Our value proposition lies in vertical integration.

We provide complete solutions — design support, roll forming, bending, robotic welding, laser cutting, powder coating, and modular assembly — all within a single facility.

This integrated model eliminates inter-supplier coordination, shortens lead times, and ensures uniform quality across the entire production lifecycle. For OEMs, that means one partner, one process, and complete accountability.

How is MIF helping OEMs achieve lighter, stronger structures through customised tubular and roll-formed solutions?

Almost every equipment segment can benefit from lightweight, high-strength tubular solutions — whether it’s cabins, chassis sub-frames, or protective structures.

Our ROPS/FOPS-certified cabins and structural roll-formed assemblies exemplify how smart material use and forming precision can reduce weight while enhancing safety and durability. We’re continuously exploring new geometries and materials that strike the right balance between strength, form, and manufacturability.

How is MIF supporting global OEMs with components made in India for both domestic and export platforms?

That’s a major focus area for us. We work with several international OEMs who rely on MIF for both domestic and export supply.

Our manufacturing and quality systems are aligned with international compliance requirements, ensuring consistent performance across markets.

With digital traceability, lean manufacturing, and global logistics readiness, we enable OEMs to integrate Indian-made components seamlessly into their global platforms.

What role does early design collaboration play in MIF’s partnerships with OEMs when developing new platforms?

It’s absolutely critical. Early design collaboration reduces downstream costs, shortens time-to-market, and ensures manufacturability from day one. At MIF, we engage with OEM engineering teams right from the concept stage — co-developing profile geometries, optimizing tool paths, and validating designs through simulations. This design partnership approach has consistently helped our clients achieve faster launches, improved efficiency, and a more reliable end product.

Mother India Forming’s participation at EXCON 2025 is a reflection of India’s engineering maturity and manufacturing confidence. By combining integration, innovation, and sustainability, MIF is demonstrating that world-class quality and responsible manufacturing can be achieved right here in India — consistently, competitively, and collaboratively.