Digital Technologies Redefine Project Management Consultancy in Infrastructure

Digital adoption is transforming project management consultancy from traditional supervision to data-driven decision-making. With BIM, GIS, and advanced project management platforms, PMCs are improving coordination, reducing risk, and enhancing execution efficiency, enabling more predictable, transparent, and sustainable delivery of complex infrastructure projects

How is Project Management Consultancy evolving with digital technologies in construction?

Project Management Consultancy (PMC) has shifted from traditional oversight to a digitally-enabled strategic role in construction. Digital technologies provide PMCs with real-time project visibility, enabling predictive decision-making rather than reactive monitoring. Cloud-based platforms, IoT sensors, and digital reporting tools allow PMCs to track progress, resource allocation, and schedule adherence seamlessly across multiple sites. This evolution empowers PMCs to coordinate complex projects more efficiently, manage risks proactively, and ensure accountability among stakeholders. Data-driven workflows also enhance transparency, allowing informed interventions at early stages to prevent delays or cost overruns. In essence, digital adoption transforms PMC from a supervisory role into a decision-making enabler, aligning execution with strategic project goals while supporting sustainable and optimized construction delivery.

What does digital construction mean, and how are BIM and GIS reshaping planning and execution?

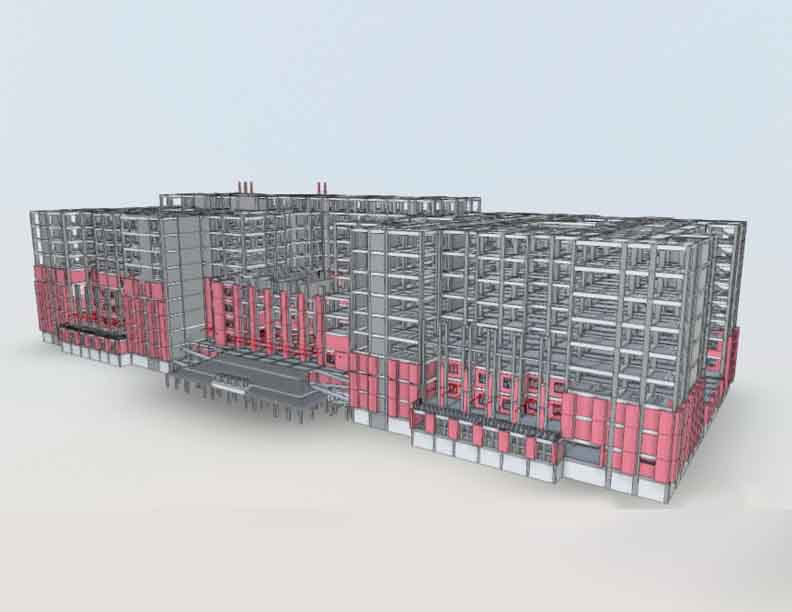

Digital construction represents the integration of information technology, data analytics, and modeling tools into construction processes to improve efficiency and predictability. BIM (Building Information Modeling) provides a multidimensional view of the project, enabling precise design, clash detection, and coordination before construction begins. GIS (Geographic Information Systems) adds spatial context, allowing planners to evaluate site conditions, environmental factors, and infrastructure connectivity. Together, BIM and GIS facilitate holistic planning, bridging the gap between design intent and site realities. This integration enables PMCs and project teams to simulate construction sequences, anticipate challenges, and optimize resource deployment. The result is a more accurate, collaborative, and risk-aware project execution, reducing inefficiencies and enhancing long-term operational outcomes.

How do BIM workflows enhance design coordination and communication among architects, engineers, and contractors?

BIM workflows serve as a centralized collaborative platform where architects, engineers, and contractors can share models, track changes, and resolve conflicts before they manifest on-site. Multidisciplinary coordination becomes more transparent, as design alterations are automatically updated across all stakeholders, ensuring everyone works with the latest information. Clash detection tools identify structural or service conflicts early, reducing costly rework. Visual models support clearer communication for non-technical stakeholders, bridging gaps between conceptual design and practical execution. By creating a shared digital environment, BIM workflows streamline approvals, enhance accountability, and foster collaborative problem-solving, transforming what was once fragmented communication into continuous, integrated project management.

How can digital planning and construction sequencing help PMC teams minimize rework, waste, and site inefficiencies?

Digital planning, powered by BIM and construction sequencing tools, allows PMCs to visualize and simulate every stage of construction before breaking ground. By mapping the sequence of tasks and resources in a 4D or 5D environment, potential conflicts and bottlenecks are detected early, reducing unplanned rework. Material requirements can be accurately forecasted, minimizing waste and optimizing procurement. Sequencing also enhances coordination between subcontractors and site teams, ensuring activities occur in the correct order and on schedule. Continuous monitoring through digital dashboards helps PMCs track deviations in real-time, enabling timely corrective actions. Overall, this approach reduces inefficiencies, prevents cost leakage, and supports sustainable construction practices, ensuring projects are delivered on time without compromising quality.

As someone experienced in the market, how do you believe technology (such as GIS, BIM, and project management tools) is shaping the future workforce in infrastructure consultancy and execution, and how is RIPL leveraging it in projects? Technology is reshaping the infrastructure workforce by embedding digital tools into every stage of project delivery. RIPL uses BIM to coordinate architectural, structural, and MEP designs, detecting clashes early and improving on-site execution. GIS is employed to analyse site conditions, optimize resource deployment, and manage geospatial data for large-scale infrastructure projects. Project management platforms provide real-time monitoring, progress tracking, and data-driven decision-making, enabling teams to respond quickly to delays or issues. This integration creates new roles such as BIM coordinators, GIS analysts, and digital planners, making technical proficiency essential for future-ready teams. By leveraging these technologies, RIPL ensures that field teams and consultants operate efficiently, reduce rework and material waste, and maintain project timelines, demonstrating how digital adoption directly shapes workforce capabilities and project outcomes.