PreZZure at EXCON displays Smart, Sustainable Hydraulic Innovations

PreZZure is showcasing next-generation hydraulic technologies focused on efficiency, safety, and sustainability. With advanced valves, system integration capabilities, and customer-driven development, the company aims to empower OEMs with smarter, faster, and globally competitive solutions for construction and road machinery applications.

What innovative hydraulic systems or technologies is PreZZure showcasing at EXCON this year?

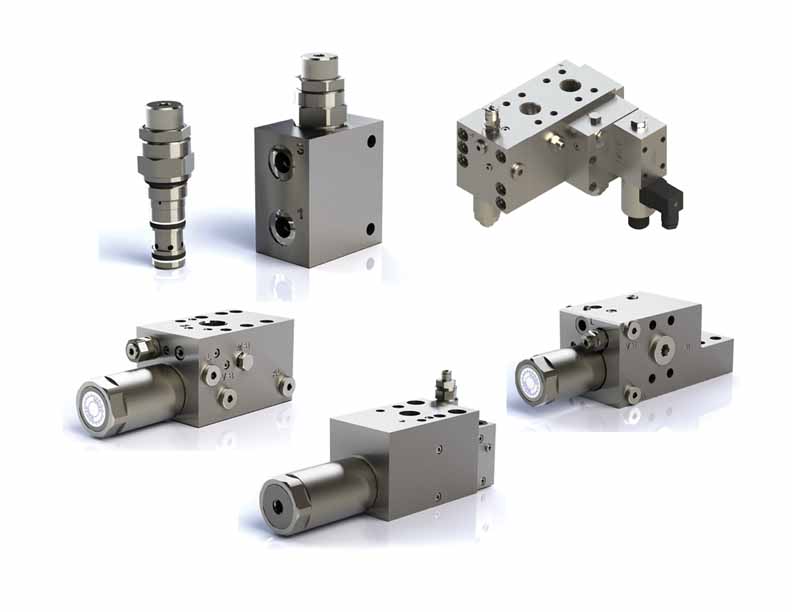

PreZZure is introducing a range of advanced hydraulic technologies at EXCON this year, including its newly developed Self-Levelling Valve, designed to replace traditional mechanical systems for maintaining balance between boom and bucket movements. The company is also showcasing a hydraulic Quick Hitch Valve that enables faster and safer attachment changes for construction and agricultural machinery. Additionally, Prezzure Hydraulics is presenting Charging Valves for accumulators, high-precision Proportional Valves, a specialized Hydraulic Hammer Valve (model RFP-A-EV-VLP-2), and Pneumatic Operated Valves available in both normally open and normally closed configurations across multiple cavity sizes. These innovations emphasize enhanced control, safety, versatility, and operational efficiency for modern hydraulic applications.

How are your solutions enhancing efficiency and reliability for the construction and road machinery sectors?

We have a very competitive market around us as all our product are imported from Germany and Italy. But our product cost justifies our product quality, which helps construction and machinery for reliable machines for use.

Could you elaborate on how your system integration expertise benefits OEM partners?

Streamlined Product Development: System integration expertise allows an OEM to quickly and seamlessly incorporate specialized components (hardware, software, or entire subsystems) from a partner. This eliminates the need for the OEM to develop these complex elements in-house from scratch.

How does your development process enable quick and tailored solutions for customers?

Each sprint ends with a review, allowing the customer to provide immediate feedback. This ensures that any necessary course corrections happen early and are small, preventing major, costly redesigns late in the project.

In what ways do customer collaborations drive your innovation and R&D initiatives?

OEMs provide the ultimate performance metrics. We receive data on how our integrated components perform under real-world stress, which drives the R&D needed to boost reliability, efficiency, and longevity.

How is PreZZure advancing technology in mobile and industrial hydraulics?

“We engineer your progress for a sustainable tomorrow” We make our contribution to sustainable and energy-efficient machines in many industries. The machines equipped with our valves should be as safe and energy-saving as possible.

What initiatives are you taking to promote sustainability and energy efficiency in your products?

We focus on developing highly integrated, smaller components and lighter enclosures. Using fewer raw materials, particularly plastics and rare earth minerals, directly reduces the product’s embodied carbon footprint.

How are you leveraging partnerships to expand into international and emerging markets?

In high-growth but complex emerging markets, we often form deeper alliances with local technology leaders.

What’s your long-term vision for the role of hydraulics in next-generation construction equipment?

Hydraulics will be integrated with electric drives in a hybrid fashion. For example, the vehicle drive train

may be electric, but the implements (boom, bucket, blade) will still be powered by highly optimized hydraulic systems.